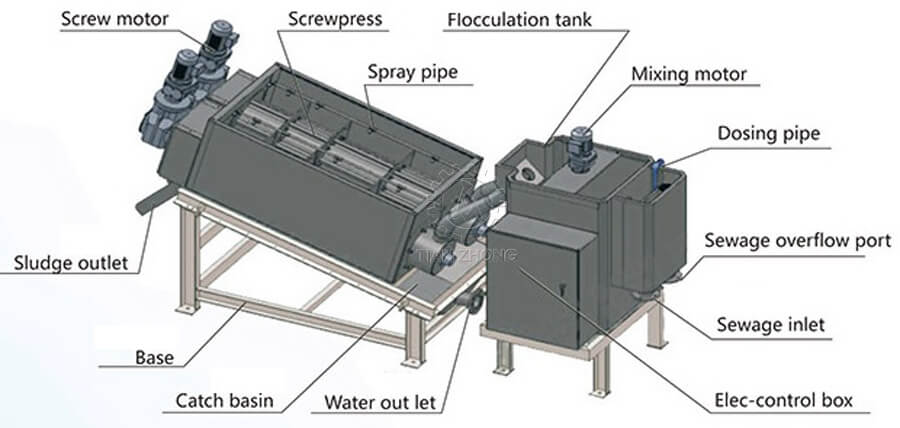

Sludge dewatering machine is a new type of solid-liquid separation equipment that adopts the screw extrusion principle. The water content of the final product solids (or filter cake) depends on the quality of the water sludge. You can send us specific pictures of raw materials, and our project manager will evaluate the moisture content of the solid after dewatering according to your specific raw materials.

The rotation of the screw shaft produces a great internal pressure under the blocking action of the backpressure plate while pushing the sludge transportation so that the volume is continuously reduced, and the purpose of dewatering is finally achieved.

➤ Industrial wastewater coagulation sedimentation sludge

➤ Urban sewage treatment surplus sludge

➤ Community sewage sludge

➤ Adding chemicals to agglomerate sludge in the water purification plant

➤ Water and fertilizer treatment of surplus sludge

➤ Solid-liquid separation in the factory manufacturing process

The main shaft adopts the self-developed technology of taper shaft and variable pitch. The sludge increases the axial and radial bidirectional pressure during the operation of the screw shaft, which improves the dehydration rate and work efficiency. [Read also: Screw Press Sludge Dewatering: An Effective Solution for Wastewater Treatment]

Using laser cutting and leveling technology processing technology, the flatness of the laminated sheet increases the dewatering rate of the equipment, and the sludge cake is dried to clear the water effect, and the stacked screw sludge dewatering machine will not leak mud, run mud, and appear thin mud soup. Phenomenon.

The body of the sludge dewatering machine is made of 304 stainless steel, which is corrosion-resistant and wear-resistant.

Due to the use of low-speed screw extrusion technology, the power consumption is very low. At the same time, it is equipped with an automatic spray system, which avoids clogging and does not require a lot of water to rinse.

Furui Machinery Co.,Ltd is a top screw press dewatering machine manufacturer.

If you want to know more details, welcome to leave a message.

Call Us/WhatsApp

+86 193 3712 3736Email Us

inquiry03@furuimachinery.comOffice Address

No.78 Puhui RD, Jinshui District, Zhengzhou, China