Wastewater treatment is a critical process that involves removing impurities from water to make it safe for disposal or reuse. One significant challenge in wastewater treatment is sludge dewatering, which involves separating solid and liquid components from the wastewater. Screw press sludge dewatering is a proven technology that can effectively dewater sludge, resulting in reduced volume and improved solids concentration.

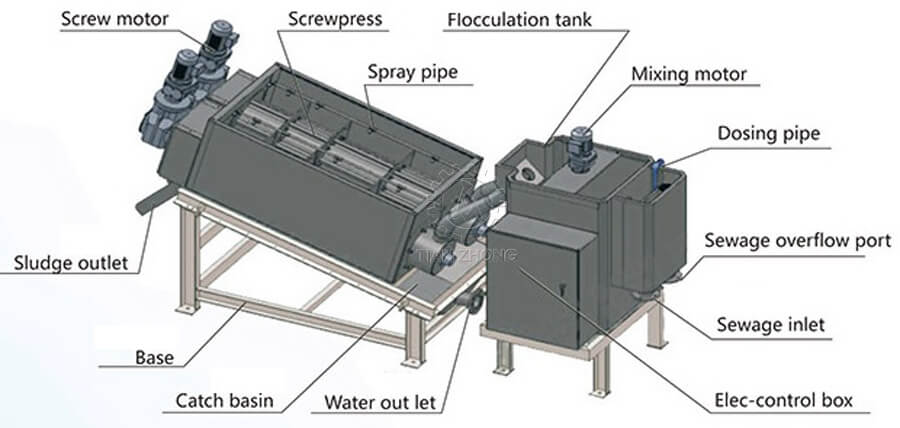

Screw press sludge dewatering machine works by using a series of rotating screws to gradually increase the pressure on the sludge. The sludge is fed into the system through a hopper, where it is mixed with a flocculating agent to enhance the dewatering process. The sludge is then pushed through a series of screens that gradually reduce the space between the screws, increasing the pressure on the sludge. As the pressure increases, the water is squeezed out of the sludge, resulting in a drier solid component that can be easily disposed of or reused.

The screw press sludge dewatering machine can handle a wide range of sludge types, including primary, secondary, and mixed sludge. The system can also handle high solids concentration, making it an effective solution for industries that generate large volumes of sludge.

Screw press sludge dewatering machine offers several advantages over other dewatering technologies.

➤ Firstly, it is a low-maintenance technology that requires minimal operator intervention. The system is automated, and the screws are self-cleaning, reducing the need for manual cleaning.

➤ Secondly, screw press sludge dewatering machine is energy-efficient, as it requires minimal power to operate. The system has a low noise level and produces less odor, making it an ideal solution for urban areas.

➤ Thirdly, screw press sludge dewatering machine has a small footprint, making it suitable for industries with limited space. The system can be installed indoors or outdoors, depending on the space available.

Screw press sludge dewatering machine is widely used in various industries, including food processing, chemical manufacturing, and wastewater treatment plants. The technology is particularly effective in treating sludge generated by municipal wastewater treatment plants, where large volumes of sludge are generated daily.

Screw press sludge dewatering machine is also used in the pulp and paper industry, where it is used to dewater sludge generated during the papermaking process. The technology is effective in reducing the volume of sludge, making it easier and cheaper to dispose of or reuse.

Several factors can affect the performance of screw press sludge dewatering machine.

➤ The first factor is the type of sludge being treated. Different sludge types require different flocculating agents, which can affect the dewatering process. The pH of the sludge can also affect the performance of the system, and it is essential to maintain the pH within the optimal range.

➤ The second factor is the temperature of the sludge. The dewatering process is more effective at higher temperatures, and it is essential to maintain the sludge temperature within the optimal range to achieve maximum dewatering efficiency.

➤ The third factor is the solids concentration of the sludge. Higher solids concentration can result in more efficient dewatering, and it is essential to optimize the solids concentration to achieve maximum dewatering efficiency.

Maintenance of the screw press sludge dewatering system is critical to ensure optimal performance and longevity of the system. Regular maintenance includes cleaning the screens, checking the oil levels, and inspecting the screws for wear and tear. It is also essential to replace the flocculating agent regularly to ensure maximum dewatering efficiency.

The system should be inspected regularly for leaks and other defects, and any issues should be addressed promptly to prevent downtime and costly repairs.

Screw press sludge dewatering machine offers several environmental benefits, including reduced volume of sludge, reduced transportation costs, and reduced carbon emissions. The dewatered sludge can be easily transported and disposed of, reducing the need for expensive transportation and disposal methods.

The technology also reduces the carbon footprint of the industry by reducing the need for energy-intensive dewatering methods. The low noise level and odor production also make screw press sludge dewatering machine an environmentally friendly solution for urban areas.

The cost of screw press sludge dewatering machine varies depending on several factors, including the type of system, the volume of sludge being treated, and the maintenance requirements. However, the technology offers several cost benefits, including reduced transportation costs, reduced disposal costs, and reduced energy costs.

The technology also offers a quick return on investment, and the cost can be easily offset by the savings generated by the system. It is essential to choose a system that offers a good balance between cost and performance to ensure optimal efficiency and maximum cost savings.

Screw press sludge dewatering machine is a proven technology that Henan Tianzhong Machinery Co., Ltd., can offer an effective solution for sludge dewatering. The technology is energy-efficient, low-maintenance, and has a small footprint, making it an ideal solution for various industries.

Furui Machinery Co.,Ltd is a top screw press dewatering machine manufacturer.

If you want to know more details, welcome to leave a message.

Call Us/WhatsApp

+86 193 3712 3736Email Us

inquiry03@furuimachinery.comOffice Address

No.78 Puhui RD, Jinshui District, Zhengzhou, China