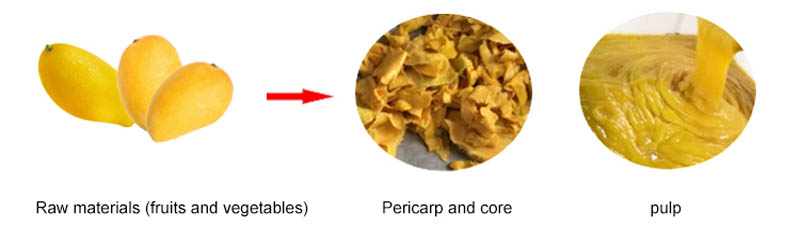

Knowing the main structures of the commercial mango juice machine can clearly know how the machine extract mango pulp.

The commercial mango juice machine consists of a fruit breaking device, a denucleating and crushing device, a beating device, a frame, a transmission and a control cabinet.

Fruit breaking device: The raw material mango enters the feeding hopper of the commercial mango juice machine from the elevator and is forcedly fed through the fruit breaking device. Then it will down the road to nuclear pressure.

Crushing and de-nucleating device: The motor is driven by a belt to make the rotor parts installed on the splines rotate at a high speed. After the mango is broken, the mango enters the cavity, and the screw feeds the de-nucleating and crushing blades to smash the material, and the fine particles on the core are smashed. The mango pulp is further separated by the high-speed rotation of the scraper at the rear end. Due to the existence of centrifugal force, the juice and meat in the material will enter the next beating through the screen holes on the screen (the screen holes are determined according to the size of the fruit core. ), the core is discharged from the slag outlet by the slag-discharging paddle, so as to realize the automatic separation of the core from the pulp and skin. [ Read also: How do you make fruit pulp commercially? ]

Beating device: The motor is driven by a belt to make the scraper installed on the spline rotate at a high speed. When the mango pulp and skin after de-nucleating flow into the cavity, the blades between the distributing plate and the pulp receiving plate will cut each other. The mango is evenly distributed to the scraper and the screen of the commercial mango juice machine. Due to the rotating action of the scraper and the existence of the lead angle, the material moves along the cylinder to the outlet end. The moving trajectory is spiral, and the mango is on the scraper. In the process of moving between the sieve and the sieve, they are crushed by centrifugal force.

The juice and meat (which has become pulpy) are sent to the next process through the sieve hole, and the skin is discharged from the slag hopper to achieve automatic separation. For the purpose of adjusting the lead angle of the scraper (adjusted on the special adjustment seat) and the gap between the scraper and the screen, different beating speeds can be changed, and the screen of different specifications can be changed to obtain satisfactory results.

Contact us to get more information about the commercial mango juice machine.

Furui Machinery Co.,Ltd is a top screw press dewatering machine manufacturer.

If you want to know more details, welcome to leave a message.

Call Us/WhatsApp

+86 193 3712 3736Email Us

inquiry03@furuimachinery.comOffice Address

No.78 Puhui RD, Jinshui District, Zhengzhou, China