Have you ever wondered what happens to the cow dung after it is collected from the barn? Well, one of the important steps in utilizing cow dung for various purposes is separating or removing water from it. This process is crucial because the excess moisture in cow dung can affect its usability and efficiency in applications such as organic fertilizers, biogas production, and even traditional building materials. Henan Tianzhong specially designed a dehydrator to separate/remove water from cow dung for this phenomenon which is efficient. So how do you separate/remove water from cow dung? Sun drying or mechanical separation?

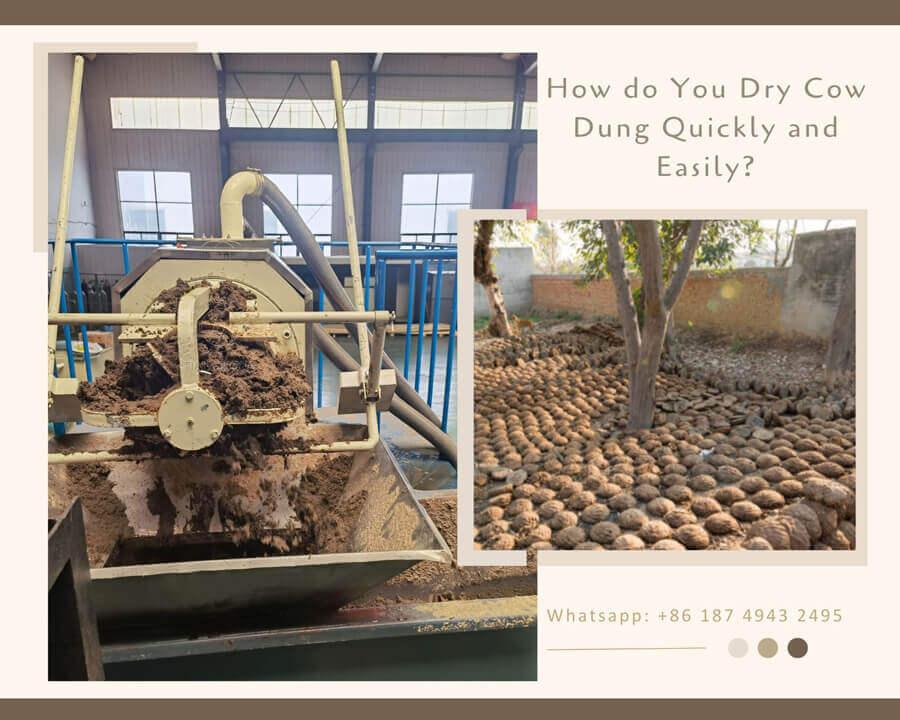

One of the simplest and most traditional methods to remove water from cow dung is through sun drying. This method takes advantage of the natural heat and energy from the sun to evaporate the moisture content in the dung. To begin the process, the cow dung is spread out in thin layers on a clean and dry surface, such as a concrete floor or a plastic sheet. By exposing the cow dung to direct sunlight, the heat energy from the sun causes the water in the dung to evaporate into the atmosphere, leaving behind drier cow dung.

It is important to ensure that the cow dung is spread out evenly and not piled up, as this can hinder the drying process. Additionally, turning or flipping the dung periodically can help speed up the drying process by exposing different parts of the dung to sunlight. Depending on the weather conditions, it may take several days for the cow dung to completely dry out.

In addition to sun drying, mechanical separation is another efficient method for removing water from cow dung. This technique involves the use of machines or equipment specifically designed to separate solids from liquids. One common method is the use of a screw press, which employs a rotating screw mechanism to compress the cow dung and separate the liquid from the solid components.

The process begins by feeding the wet cow dung into the screw press. As the screw rotates, it applies pressure to the cow dung, forcing the liquid to separate from the solid matter. The liquid portion, which contains the water and other dissolved substances, is then drained or collected separately, leaving behind drier cow dung.

Mechanical separation offers several advantages over sun drying.

⚫ It is a more efficient and controlled process, allowing for faster water removal and consistent drying.

⚫ Additionally, it can be used for large-scale operations, making it suitable for commercial and industrial applications.

⚫ However, mechanical separation methods may require initial investment in equipment and machinery, which could be a limiting factor for smaller-scale operations.

Separating or removing water from cow dung is a crucial step in utilizing this valuable resource effectively. Whether it is through traditional sun drying, mechanical separation, or composting, each method offers its own advantages and applications. Sun drying is a simple and cost-effective method that utilizes natural solar energy, while mechanical separation provides a more controlled and efficient process suitable for large-scale operations. By choosing the appropriate method based on the scale and requirements of your operation, you can ensure that the water content in cow dung is minimized, maximizing its potential for various beneficial applications. If you are interested in cow dung dewatering machine, welcome to contact us.

Furui Machinery Co.,Ltd is a top screw press dewatering machine manufacturer.

If you want to know more details, welcome to leave a message.

Call Us/WhatsApp

+86 193 3712 3736Email Us

inquiry03@furuimachinery.comOffice Address

No.78 Puhui RD, Jinshui District, Zhengzhou, China