Food waste is a growing concern globally. It is estimated that one-third of all food produced in the world is wasted, which amounts to 1.3 billion tonnes per year. This waste not only puts a strain on the environment but also on resources such as water and energy. However, there are ways to reduce food waste, and one such solution is the food waste screw press.

A food waste screw press is a machine that processes food waste and separates it into solid and liquid components. The solid component can be used for composting or as animal feed, while the liquid component can be sent to a wastewater treatment plant. [Read also: Screw type press dewatering machine]

Using a food waste screw press has many benefits.

• Firstly, it reduces the amount of food waste that goes to landfills, which in turn reduces greenhouse gas emissions.

• Secondly, it produces valuable by-products such as compost and animal feed. Thirdly, it saves money by reducing waste disposal costs.

• Finally, it is an environmentally friendly solution that aligns with sustainable development goals.

Food waste screw presses are available in different sizes and capacities, which makes them suitable for various applications. They can be used in households, restaurants, supermarkets, and industrial facilities.

Now that we know the benefits let’s explore how it works.

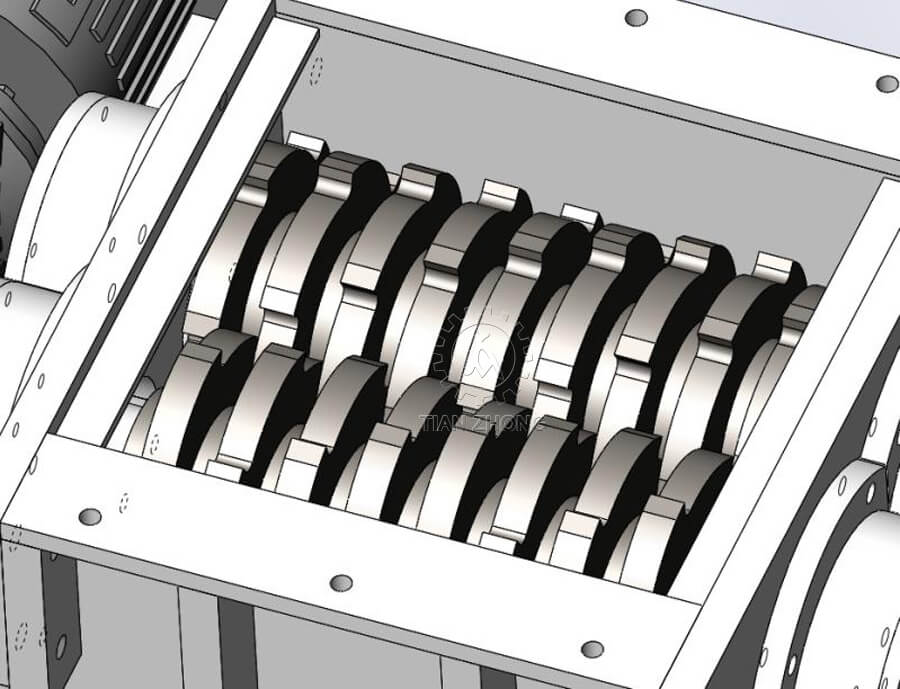

A food waste screw press works by using a rotating screw to crush and compress food waste. The food waste is fed into a hopper, screw presses against a perforated screen. As the screw rotates, the pressure on the waste increases, and the liquid component is squeezed out through the screen. The solid component is discharged from the end of the screw and collected in a bin or conveyor.

The liquid component is sent to a wastewater treatment plant for further processing. The processed liquid can be used for irrigation or discharged into a water body.

Food waste screw presses are equipped with safety features such as overload protection, emergency stop, and interlocks to prevent accidents. They are also easy to operate and maintain, which makes them a popular choice for waste management.

A food waste screw press can process a wide range of feedstocks. Some common feedstocks include fruit and vegetable waste, meat and fish waste, dairy waste, bakery waste, and food packaging waste.

It is essential to sort the feedstock before processing to remove contaminants such as plastic, metal, and glass. Contaminated feedstock can damage the machine and affect the quality of the by-products.

Food waste screw presses can also process mixed waste, which is a combination of food waste and other organic waste such as yard waste. However, mixed waste processing requires additional equipment and is more complex than food waste processing.

Regular maintenance of a food waste screw press is essential to ensure its optimal performance and longevity. Some maintenance tasks include cleaning the machine, lubricating the moving parts, inspecting the screens and blades, and checking the safety features.

It is also essential to train the operators on how to use the machine correctly and safely. Operators should be familiar with the safety features, emergency procedures, and maintenance tasks.

Regular maintenance and proper training can reduce downtime, extend the machine’s lifespan, and ensure safe operation.

The cost of a food waste screw press varies depending on the type, size, and capacity. Horizontal screw presses are more expensive than vertical screw presses due to their higher capacity and complexity.

However, the cost of a food waste screw press can be offset by the savings in waste disposal costs and the revenue generated from the by-products. Compost and animal feed are valuable products that can be sold or used for internal purposes, such as landscaping or livestock feeding.

The return on investment of a food waste screw press depends on various factors such as the feedstock, the processing capacity, and the local regulations. It is essential to conduct a cost-benefit analysis before investing in a food waste screw press.

In conclusion, the Food Waste Screw Press is a sustainable solution for food waste management. Its efficiency, ease of use, and positive environmental impacts make it an attractive option for businesses of all sizes. The machine’s ability to create new revenue streams and help businesses meet regulatory requirements further enhances its appeal. Welcome to contact us to get more information.

Furui Machinery Co.,Ltd is a top screw press dewatering machine manufacturer.

If you want to know more details, welcome to leave a message.

Call Us/WhatsApp

+86 193 3712 3736Email Us

inquiry03@furuimachinery.comOffice Address

No.78 Puhui RD, Jinshui District, Zhengzhou, China